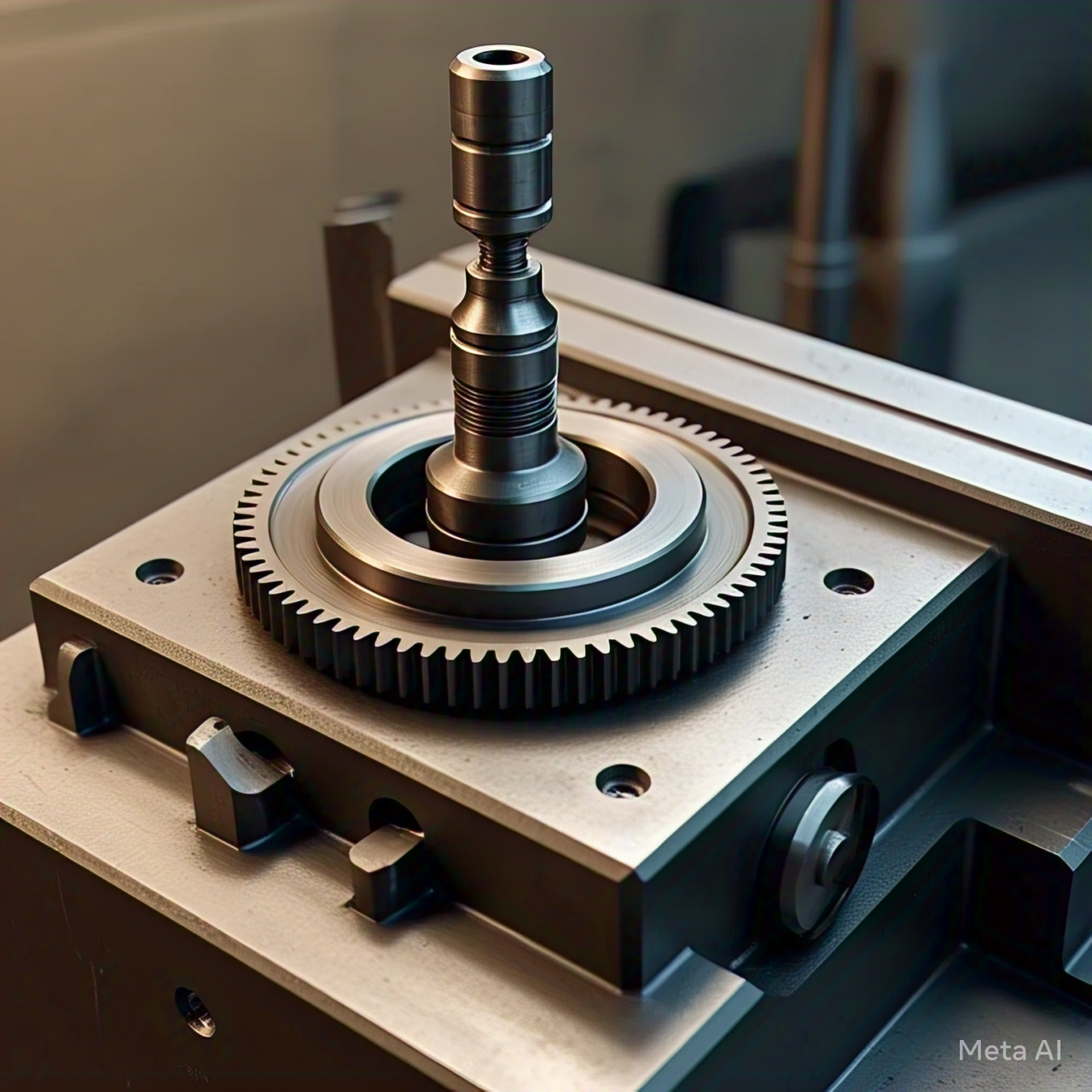

In the machining field, the need for solidified metal apparatuses is unavoidable because they are used to cut, shape, and remove material from the workpiece. One such essential metal apparatus is the gear cutter tool. It is more useful for manufacturing quality gears that are utilized in different mechanical systems.

Typically, gear cutter tools are accessed to create teeth on gear blanks with the help of different processes such as hobbing, shaping, and milling. In the end, you can achieve various gear types and precision levels. Keep scrolling to learn in-depth about the gear cutter tools’ uses and applications!

Different types of gear cutter tools

When it comes to gear cutter tools, you have the following types to be used for specific purposes and needs. You can reach the reliable gear cutting tools manufacturers india to get access to these tools.

- Gear hobs – This tool is widely utilized for gear hobbing. Hobbing is a process of progressively generating gear teeth.

- Gear shaper cutters – It is ideal for shaping gear teeth perfectly and turning them into a quality workpiece.

- Gear grinding wheels – These are more useful for obtaining high precision and surface finish.

- Gear milling cutters – This versatile tool is used to remove excess materials properly to create gear teeth

Key uses of gear cutter tools

Gear cutter tools play a vital role in shaping and manufacturing gears. Here are the key uses of this tool.

- Gear production

- Shaping and finishing

- Repair and maintenance

- Production of custom gear design

- High-volume production of gears

What to look up when buying

If you are going to buy gear cutter tools for the first time, make sure you pay attention to these elements. It helps you to make the right purchase decision that fulfills your needs.

- Gear type

- Material

- Accuracy and precision

- Production requirements

- Chip thickness

- Cutting speed and lubrication

- Cutting fluids

Remember that you have to invest more money to get this tool, so be careful and check the vital factors twice. Likewise, make sure you join hands with a reliable manufacturer to get quality gear-cutting tools at affordable prices.

Common applications for gear cutting tool

Gear cutter tools have a wide range of applications across several industries because they play a vital role in machinery and mechanical systems. Here are the most common applications of gear-cutting tools in various industries.

- Automotive industry – This tool helps manufacture gears for transmissions, gearboxes, and differentials in vehicles.

- Robotics – It helps craft gears for enough control and precise movement in robotic systems.

- Industrial machinery – Gear cutter helps in creating gears for heavy-duty equipment such as pumps, machine tools, conveyors, and compressors.

- Aerospace – It produces high-precision and top-quality gears for navigation systems, landing gear mechanisms, and aircraft engines.

- Medical equipment – It is more beneficial in making miniature gears for devices such as imaging systems, surgical robots, and diagnostic tools.

- Consumer electronics – It produces small and intricate gears for gadgets such as clocks and printers.

All of these applications need specific gear designs for perfect working and great performance. This is why gear cutter tools are available in different types to meet unique needs. According to your project needs, you must accommodate the right type and enjoy its benefits to the core.