Introduction

In the heart of modern manufacturing, where precision meets innovation, a group of elements known as metalloids is quietly revolutionizing the industry. These chameleons of the periodic table—neither fully metal nor nonmetal—power everything from smartphones to solar panels. But what makes metalloids like silicon, germanium, and boron so special in precision manufacturing? And how does CNC (Computer Numerical Control) machining unlock their potential? This article dives into the fascinating world of metalloids, exploring their unique properties, their critical role in CNC machining, and their future in high-tech industries. Whether you’re a tech enthusiast or an industry professional, prepare to discover why metalloids are the unsung heroes of modern manufacturing.

Understanding Metalloids: Chemistry and Periodic Table Context

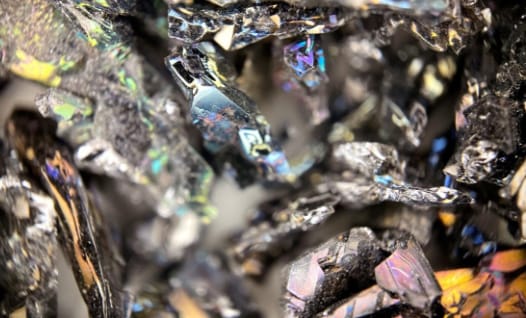

Metalloids sit in a curious spot on the periodic table, straddling the line between metals and nonmetals. Think of them as the periodic table’s “middle children,” with elements like boron (B), silicon (Si), germanium (Ge), arsenic (As), antimony (Sb), and tellurium (Te) occupying this unique zone. Located along the diagonal “staircase” from boron to tellurium, these elements blend metallic luster with nonmetallic brittleness, making them ideal for specialized applications.

Their position in the periodic table—near groups 13 to 16—gives them intermediate electronegativity and covalent bonding tendencies. This is why silicon and germanium shine as semiconductors, conducting electricity just enough to power the chips in your laptop. Their chemistry isn’t just academic trivia; it directly influences how they behave under the precise blades of CNC machines. For manufacturers, understanding metalloids’ periodic table context is the first step to mastering their machining potential.

Table 1: Metalloids and Their Periodic Table Properties

| Element | Atomic Number | Periodic Table Position | Electronegativity | Key Property | Common Application |

| Boron (B) | 5 | Period 2, Group 13 | 2.04 | High hardness, lightweight | Boron carbide tools |

| Silicon (Si) | 14 | Period 3, Group 14 | 1.90 | Semiconductor, brittle | Microchips, solar panels |

| Germanium (Ge) | 32 | Period 4, Group 14 | 2.01 | Semiconductor, infrared optics | Optical lenses |

| Arsenic (As) | 33 | Period 4, Group 15 | 2.18 | Toxic, semiconductor compound | Gallium arsenide chips |

| Antimony (Sb) | 51 | Period 5, Group 15 | 2.05 | Brittle, alloy component | Flame retardants |

| Tellurium (Te) | 52 | Period 5, Group 16 | 2.10 | Semiconductor, photoconductive | Solar cells, sensors |

Unique Properties of Metalloids Shaping CNC Machining

Metalloids are nature’s paradox—hard yet brittle, conductive yet not quite metallic. Take silicon: with a Mohs hardness of 7, it’s tougher than many metals but shatters like glass if mishandled. This duality makes metalloids both a dream and a challenge for CNC machining. Their semiconductor properties, for instance, make silicon and germanium indispensable in electronics, while boron’s extreme hardness powers cutting tools.

These properties directly impact CNC machining. The brittleness of metalloids demands ultra-precise tools, often diamond or cubic boron nitride, to avoid cracks. Their high melting points (silicon at 1414°C) mean CNC machines must manage heat carefully to prevent warping. Yet, it’s this very challenge that makes metalloids exciting—they push CNC technology to new heights, driving innovation in tool design and machining techniques.

Applications of Metalloids in CNC-Driven Semiconductor Manufacturing

The semiconductor industry is where metalloids truly shine. Silicon, the backbone of microchips, is sliced into razor-thin wafers using CNC machines with tolerances as tight as 0.001 mm. Germanium, prized for its infrared transparency, is machined into lenses for night-vision systems. Even arsenic, in the form of gallium arsenide, powers high-speed 5G chips.

CNC machining is the unsung hero here, enabling the precision needed to transform raw metalloids into functional components. For example, a silicon wafer’s surface must be polished to near-atomic smoothness, a feat only achievable with advanced CNC grinding and polishing systems. As demand for smaller, faster devices grows—global semiconductor sales hit $555.9 billion in 2022, per the Semiconductor Industry Association—CNC machining of metalloids is more critical than ever.

Table 2: Metalloid Applications in CNC Machining

| Metalloid | CNC Machining Process | Application | Industry | Precision Requirement | Market Size (2023) |

| Silicon | Wafer cutting, polishing | Microchips, solar panels | Electronics, Renewable Energy | <0.001 mm tolerance | $100B (solar), $500B (chips) |

| Germanium | Lens shaping, grinding | Infrared optics, semiconductors | Defense, Telecom | Sub-micron surface finish | $2.5B (optics market) |

| Boron | Tool fabrication, coating | Boron carbide cutting tools | Manufacturing | High wear resistance | $1.2B (tooling market) |

| Arsenic | Compound wafer processing | Gallium arsenide chips | Telecom, Photonics | 0.01 mm thickness control | $10B (compound semis) |

| Tellurium | Thin-film deposition, cutting | Solar cells, sensors | Renewable Energy, IoT | Uniform film thickness | $3B (thin-film solar) |

Overcoming Brittleness: Challenges in Machining Metalloids

Machining metalloids is like walking a tightrope. Their brittleness means even a slight miscalculation can cause micro-cracks, ruining a costly silicon wafer. Their hardness chews through standard tools, driving up costs—diamond tools can cost $500-$2000 each, per industry estimates. Heat is another foe; excessive temperatures during machining can alter a metalloid’s crystalline structure, wrecking its performance.

The solution? Precision and innovation. Manufacturers use ultra-low feed rates (as low as 0.01 mm/rev) and specialized coolants to minimize stress. Laser-assisted CNC machining, which softens the material with a focused beam, is gaining traction, reducing crack risks by up to 30%, according to a 2023 study in Journal of Manufacturing Processes. These advancements make metalloid machining not just possible but increasingly efficient.

Advanced CNC Techniques for Metalloid Processing

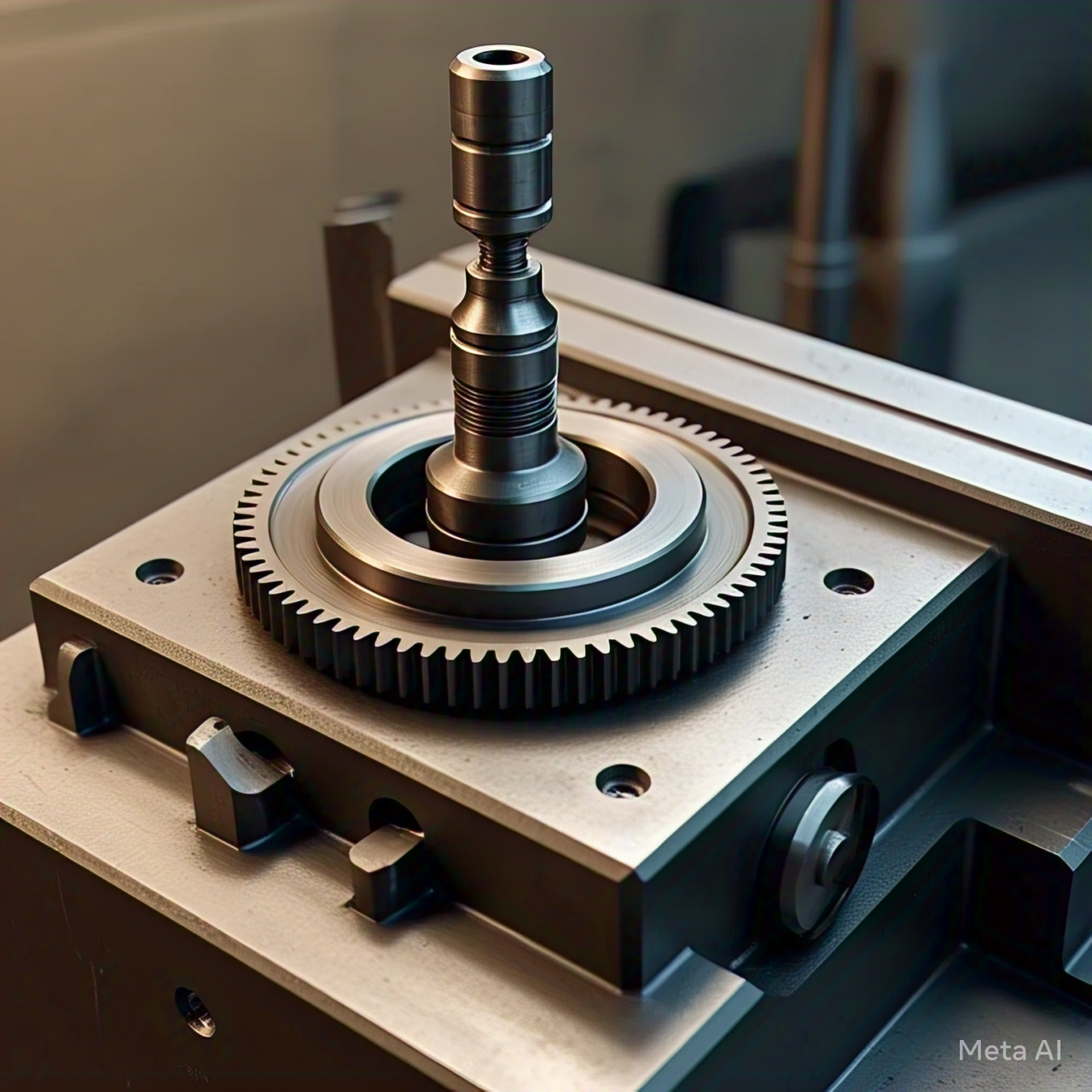

To tame metalloids, CNC machining has evolved into a high-tech art form. Diamond-tipped tools, vibrating at ultrasonic frequencies, slice through silicon with surgical precision. Hybrid CNC systems, combining laser and mechanical cutting, achieve surface finishes smoother than 10 nanometers. Chemical-mechanical polishing (CMP), often paired with CNC, ensures wafers meet the semiconductor industry’s exacting standards.

These techniques aren’t cheap—a high-end CNC machine for metalloid processing can cost $500,000—but they’re worth it. A 2024 report by MarketsandMarkets predicts the CNC machine market will hit $100 billion by 2030, driven partly by demand for metalloid-based components. For manufacturers, investing in these technologies is a ticket to staying competitive in the high-stakes world of precision manufacturing.

Table 3: CNC Techniques for Metalloid Machining

| Technique | Application | Advantage | Cost (USD) | Efficiency Gain | Adoption Rate (2024) |

| Diamond Tool Machining | Silicon wafer cutting | High precision, low tool wear | $500-$2000/tool | 20% faster than carbide | 80% (semiconductor) |

| Ultrasonic-Assisted CNC | Germanium lens shaping | Reduces cracks by 25% | $50,000/system | 15% less waste | 60% (optics) |

| Laser-Assisted CNC | Boron carbide processing | Minimizes thermal damage | $100,000/system | 30% crack reduction | 45% (tooling) |

| Chemical-Mechanical Polishing | Wafer surface finishing | Atomic-level smoothness | $10,000/process | 50% better finish | 90% (chips) |

| Hybrid CNC (Laser+Mechanical) | Gallium arsenide machining | Combines speed and precision | $200,000/system | 40% faster processing | 30% (photonics) |

Case Studies: Silicon and Germanium in Precision CNC Machining

Let’s zoom in on two metalloid superstars: silicon and germanium. Silicon wafers, the foundation of every microchip, undergo a grueling CNC process. First, a silicon ingot is sliced into wafers using wire saws guided by CNC systems. Then, CNC grinders and polishers refine the surface to a mirror finish. A single wafer, costing $100-$500, can yield thousands of chips, but one crack means starting over.

Germanium, meanwhile, is a niche player in infrared optics. CNC machines shape germanium into lenses with sub-micron precision, critical for defense systems. A 2023 case study by a leading optics firm showed that CNC machining reduced germanium lens production time by 25% compared to traditional methods, saving $1 million annually. These stories highlight how CNC machining turns metalloids into high-value products.

Future Horizons: Metalloids in Emerging Technologies and CNC Innovation

The future of metalloids is dazzling. Silicon remains king in solar and chip manufacturing, but germanium is stealing the spotlight in quantum computing, where its unique lattice structure supports qubits. Tellurium, paired with cadmium, is driving next-gen solar cells, with efficiency rates climbing to 22%, per a 2024 Nature Energy study. Arsenic-based compounds like gallium arsenide are fueling 5G and photonics growth.

CNC machining will evolve alongside these trends. AI-driven CNC systems, already in development, could optimize cutting paths in real time, boosting efficiency by 20%. As metalloids power emerging technologies, CNC machining will remain the bridge between raw elements and cutting-edge innovation, ensuring manufacturers stay ahead in a $4 trillion global tech market.

From Periodic Table to Production Line: Metalloids’ Role in Manufacturing Evolution

Metalloids are more than just elements—they’re the spark igniting precision manufacturing’s future. Their periodic table position gives them the perfect blend of properties for high-tech applications, while CNC machining unlocks their potential with unmatched precision. From silicon chips to germanium lenses, metalloids are reshaping industries, and CNC technology is the key to making it happen.

For manufacturers, the message is clear: embrace metalloids and invest in advanced CNC solutions. The rewards—higher efficiency, lower costs, and a competitive edge—are worth the effort. As we stand on the cusp of a new era in manufacturing, metalloids and CNC machining are poised to lead the charge, turning periodic table curiosities into real-world game-changers.

And if you’re curious to dig deeper, parts of this piece drew inspiration from an insightful article by the folks at from-table-to-toolwhere-are-metalloids-located-on-the-periodic-table-for-cnc-efficiency—click here to explore more on how metalloids analysis are impacting manufacturing.

FAQ:

1. What are metalloids, and why are they important in manufacturing?

Answer: Metalloids, such as silicon, germanium, and boron, are elements with properties between metals and nonmetals, located along the periodic table’s “staircase” (groups 13-16). Their semiconductor properties and high hardness make them vital in manufacturing. Silicon drives microchip production, while boron enhances cutting tools. These traits make metalloids ideal for precision CNC machining in electronics, optics, and renewable energy.

SEO Keywords: metalloids, semiconductor manufacturing, precision manufacturing

2. How are metalloids used in CNC machining?

Answer: Metalloids like silicon and germanium are processed using CNC machines to create high-precision components. Silicon is sliced into wafers for microchips with tolerances below 0.001 mm, and germanium is shaped into infrared lenses. CNC techniques like grinding, polishing, and laser cutting ensure accuracy for semiconductor and optical applications, supporting a $500 billion chip market (2023 data).

SEO Keywords: metalloids, CNC machining, silicon wafers

3. What challenges arise when machining metalloids?

Answer: Metalloids’ brittleness and hardness pose machining challenges. Silicon (Mohs hardness 7) risks cracking if mishandled, and germanium’s high cost demands precision. These issues require diamond tools ($500-$2000 each) and low feed rates (0.01 mm/rev). Innovations like ultrasonic CNC machining reduce cracks by 25%, improving reliability, per a 2023 Journal of Manufacturing Processes study.

SEO Keywords: metalloids, CNC machining challenges, diamond tools

4. Which CNC techniques are best for processing metalloids?

Answer: Effective CNC techniques for metalloids include diamond tool machining for silicon wafers, ultrasonic-assisted CNC for germanium lenses, and laser-assisted CNC for boron carbide tools. Chemical-mechanical polishing (CMP) ensures atomic-level smoothness for chips. These methods, costing $10,000-$200,000 per system, improve efficiency by up to 40%, according to a 2024 MarketsandMarkets report.

SEO Keywords: metalloids, CNC techniques, chemical-mechanical polishing

5. Why are metalloids critical for the semiconductor industry?

Answer: Metalloids like silicon and germanium are essential for semiconductors due to their selective conductivity. CNC-machined silicon wafers form microchips, fueling a $555.9 billion industry (2022, Semiconductor Industry Association). Germanium and arsenic-based compounds like gallium arsenide power high-speed 5G chips, making metalloids key to technological advancements.

SEO Keywords: metalloids, semiconductor industry, silicon chips

6. What is the future of metalloids in precision manufacturing?

Answer: Metalloids will shape manufacturing’s future. Silicon will lead in solar and chip production, while germanium gains ground in quantum computing. Tellurium-based solar cells achieve 22% efficiency (2024, Nature Energy). AI-enhanced CNC systems and hybrid machining could boost efficiency by 20%, keeping metalloids central to a $4 trillion tech market.

SEO Keywords: metalloids, future of manufacturing, quantum computing

7. How does the periodic table position of metalloids affect their machining?

Answer: Metalloids’ placement near the periodic table’s metal-nonmetal divide (groups 13-16) gives them hybrid properties like hardness and semiconductor behavior. Silicon’s covalent bonds make it brittle, requiring precise CNC tools. Germanium’s semi-metallic traits allow easier machining. These properties, tied to their periodic table position, guide CNC strategies for optimal outcomes.

SEO Keywords: metalloids, periodic table, CNC machining properties

8. How do metalloids enhance CNC machining efficiency?

Answer: Metalloids’ unique properties drive CNC machining efficiency by demanding advanced tools and techniques. Silicon’s hardness pushes the use of diamond tools, improving precision. Germanium’s optical clarity requires sub-micron CNC accuracy, enhancing lens quality. These demands spur innovations like laser-assisted CNC, cutting costs by 15-30% and boosting output, per industry studies.

SEO Keywords: metalloids, CNC machining efficiency, precision tools